Powerspan: Technology for the new energy economy

By Cathy Swirbul

Contents

New regulations require new technologies

ECO technology's Genesis

Launching a commercial product

Research and development focuses on air emissions control

The new energy economy depends on reliable electricity. Electricity-based technologies, such as computers and telecommunications, have emerged as the driving force for economic growth. The digital microprocessor has embedded every aspect of society with intelligence and dramatically reshaped American life.

Yet the world's electricity supplies are facing dramatic pressures from deregulation, increasing environmental restrictions, and surging growth in electricity demand. Electricity use has grown from 25% of energy consumption in 1970 to almost 40% today, according to the U.S. Energy Information Administration (EIA). At the same time, environmental initiatives seek to reduce power plant air emissions to a fraction of current levels.

The U.S. Environmental Protection Agency (EPA) has identified NOx, SO2 and fine particulate matter as collectively contributing to ozone formation, ozone transport and regional haze. While NOx and SO2 emissions from coal-fired power plants are regulated, a U.S. Supreme Court ruling expected in spring 2001 may further reduce limits on fine particulate matter. Mercury emissions from coal-fired plants currently are unregulated, but the U.S. EPA is scheduled to make a regulatory determination on these emissions by next month.

New regulations require new technologies

The growth and environmental demands placed on electric power systems can't be met with current energy technologies. Powerspan, based in New Durham, NH, was created to supply advanced energy technologies to meet those demands and provide a bridge from the fossil fuel era to the renewable energy era.

The company started in March 1994 as Zero Emissions Technology Inc., a manufacturer of proprietary modifications—called Arc Snubber filters—for coal-fired power plants. The product decreases particulate air emissions. In March, the company changed its name to Powerspan to better reflect its focus on next-generation energy technology. (See sidebar, Powerspan hopes to become the Cisco of energy technology)

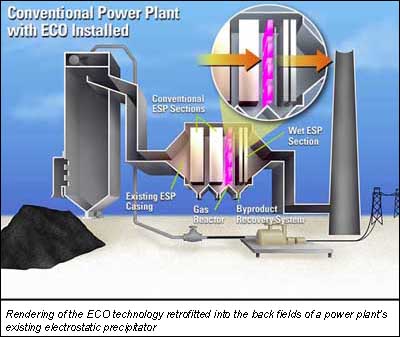

Powerspan's core technology is a cost-effective, multi-pollutant control technology for coal-fired power plants. The patented technology, called Electro-Catalytic Oxidation (ECO), functions as four separate control technologies in one system. Those technologies are: wet scrubbing or flue gas desulfurization for SO2 removal; selective catalytic reduction (SCR) for NOx removal; fabric filter for fine particulate matter removal; and activated carbon injection for mercury removal.

ECO technology breaks down gases that result from the combustion of coal into their basic elements. They are then recombined and captured as byproducts in an electrostatic precipitator. Those byproducts can become feedstock for other industrial processes.

The power generator using the ECO system may choose byproduct options, based on local market conditions and desired plant operation. Those options include the production of nitric and sulfuric acids, the production of gypsum for wall board manufacture, the addition of ammonia to produce high-quality fertilizer, or the neutralization and disposal of collected material. (Back to top)

ECO technology's Genesis

The ECO technology was conceived in fall 1996. FirstEnergy (Akron, OH), which through its electric utility operating companies serve 2.2 million electric customers in Ohio and Pennsylvania, visited Powerspan in late 1997 to observe a lab scale component of the ECO technology.

This component—a barrier discharge reactor—converts pollutants into acid mists that can be collected. Based on this demonstration and on laboratory test results, Powerspan entered into a US$4.8 million agreement with FirstEnergy in December 1997 to construct and test a larger scale, pilot unit.

The pilot unit started operating at FirstEnergy's R.E. Burger plant in July 1998. The pilot test facility is about 1/100th of commercial scale and processes 2,000–4,000 standard cubic feet per minute of coal-combustion flue gas. Based on initial pilot test results, Powerspan implemented a number of design changes and resumed testing in June 1999.

NOx emissions dropped by an average of 76% and SO2 emissions by an average of 44%. Subsequent testing conducted on the pilot by an independent stack-testing agency in April showed that the ECO technology reduced mercury emissions by more than 81.6% and fine particle emissions by 96.6%. Powerspan plans to continue operating the pilot to test design modifications quickly and gain experience with component and material reliability.

"We developed ECO with a primary focus on reducing nitrogen oxide emissions to the lowest achievable levels. These test results demonstrate that ECO has the potential to become a best available control technology for mercury and fine particulate matter as well," said Frank Alix, chairman and CEO of Powerspan.

Besides the performance results obtained at the ECO pilot, evidence exists that improvements in the technology may make it capable of removing more than 95% of both NOx and SO2 contained in coal-combustion flue gas. Research toward this goal is in progress. (Back to top)

Launching a commercial product

The Ohio Coal Development Office within the Ohio Department of Development, FirstEnergy and Powerspan are jointly funding an US$11.9 million commercial ECO installation for spring 2001 at FirstEnergy's Eastlake plant near Cleveland, OH. The 50-MW slipstream unit will draw about 110,000 standard cubic feet per minute of flue gas, representing 10% of the plant's total flue gas flow.

The demonstration is expected to reduce NOx by more than 70%, SO2 by 50%, mercury by 70% and fine particulate matter by 90%. The unit will burn Ohio coal with 2% to 4% sulfur.

"In addition to reducing emissions of multiple substances, ECO technology is expected to cost 25% to install and 50% less to operate than current NOx control systems, such as selective catalytic reduction (SCR)," said Guy Pipitone, FirstEnergy vice president. "Unlike SCR technology, ECO operates effectively when used with high-sulfur Ohio coal, and produces commercially marketable acids rather than by-products requiring disposal."

Powerspan plans to install the ECO technology in larger commercial applications in fall 2002. (Back to top)

Research and development focuses on air emissions control

Powerspan's ECO technology can be deployed in multiple sectors of the power industry, including coal-, oil- and gas-based power generation. Currently, the company is focusing some of its research and development efforts on unique applications of its electrotechnology to air emission control.

Pipitone summarized the value of Powerspan's ECO technology. "Considering the high cost of reducing nitrogen oxide emissions using available control technology, ECO should have broad market appeal. Today, there are approximately 1,200 coal-fired generating units across the country, representing more than 325,000 megawatts of capacity, that could use ECO technology."

For additional information, contact Stephanie Procopis, Powerspan's director of marketing, at (603) 859-2500, extension 20, or sprocopis@powerspancorp.com. (Back to top)

About the author: Cathy Swirbul specializes in writing for the hydro-electric industry, as well as for business-to business and business-to-consumer websites. She can be reached at cswirbul@unicom.net.

Powerspan hopes to become the Cisco of energy technology

By Cathy Swirbul

Powerspan, based in New Durham, NH, has developed multi-pollutant control technology for coal-fired power plants. The technology, called Electro-Catalytic Oxidation (ECO), helps utilities meet the growth and environmental demands placed on electric power systems. Frank Alix, Powerspan's chairman and CEO, provided Power Online an inside look at the company's challenges, strengths and future.

Q. What were the significant challenges Powerspan faced in getting started and how were they overcome?

A. Supplying new technology to a conservative industry– utilities—is always a big challenge. In the early days, we had a product called the Arc Snubber Filter. This was a low-cost retrofit that reduced particulate air emissions from power plants. Prevailing wisdom at the time did not recognize the technical problem we were trying to solve, or the technical basis of our solution, so selling was a real uphill battle.

To overcome this, we offered a money-back performance guarantee, and as a result sold a lot of product in a short period. The downside to our solution was that establishing a definitive improvement in performance was very difficult at some plants due to frequent changes in operations and fuel.

Q. What is your company doing differently from your competitors developing similar products?

A. The biggest thing we have done differently is that we started with a clear end in mind—develop a single, integrated pollution-control technology that becomes a best available control technology for SO2, NOx, fine particulate matter, and mercury, at or below the cost of a single control technology, like selective catalytic reduction or flue gas desulfurization.

We still have that as our goal, and we will not settle for anything less. It is only in the past year that the path to achieving this goal has become clear technically. We've made rapid progress because we are willing to make a lot of mistakes very quickly in order to find out what works. We have a very talented team of engineers and mechanics that build equipment almost as quickly as we can dream it up. That's the only way I know of to compress the development cycle.

Q. Where is Powerspan headed in the long term?

A. We are pursuing a number of promising areas in technology development, some related to ECO technology, such as cost-effective NOx controls for gas turbines, and some more broadly related to clean energy solutions (i.e. what comes after fossil fuels). Long term, we expect Powerspan to become the "Cisco" of energy technology. We recognize this is a lofty goal, but that is what Powerspan is all about. (Back to main story)