Pipe Restoration

The cleaning knives are made from cast specialty steel and are mechanically sharpened. The blades are hinged with a universal joint to provide flexibility for negotiating turns. A universal joint also is located between the second cleaning head and the propulsion section. These universal joints allow the device to pass through sharp bends in the pipe include-ing standard radius 90 degree welded ells and 45 degree miter-bends.

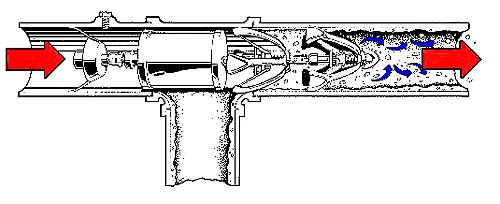

The spring-loaded cleaning knives also are adjustable to increase or decrease the tension as required, depending on the hardness and quantity of material to be removed. The blades rest on the inside of the pipe so that forward movement of the device will not cause the knives to dig in or damage the pipe wall. In fact, the final cleaning action is caused by a very fine layer of water forced between the cuffing edges of the knives and the inner surface of the pipe wall, causing the knives to "hydroplane" rather than cut into or even touch the inner surface of the pipe. The arrangement also allows the pipe to retain its "nataural lining", if desired, or any lining that has been applied to the pipe. The unit's propulsion is operating on the principle of a hydraulic ram, the unit creates a hydraulic jack-hammer effort to propel the device and also allows a 40% bypass of fluid, which flushes loosened deposits ahead of the device in a slurry form. The jackhammer action is highly effective in removing hard deposits, plus the volumes of bypass fluid, which is pulse-jet over the cuffing arms, generates a slurry of deposits. Miles of pipeline can be restored at a cleaning rate of 2-3 feet per second.

Unlike other cleaning equipment, the forward progress of the tool is seldom hampered by debris clogging in front due to the high bypass slurry volumes, if debris that has been removed from the walls of the pipe accumulates the forward progress of the equipment is automatically slowed, allowing more bypass fluid (water, or any other fluid naturally flowing through the pipe) to pass through the equipment to speed up the removal of debris. As the accumulation of debris moves ahead of the cleaning tool, the equipment automatically resumes its normal rate of cleaning. If the cleaning tool becomes lodged in the pipe because of foreign debris, flow can be restored due to the bypass design capabilities. In addition, the sucking action caused by the pressure differential created by the vibrating propulsion and the speed of the device means that the water immediately following the tool is as clean as the water being pumped into the pipeline from the source.

A special radio transmitter is attached to the unit and pinpionts the rate of advance and point-of-progress of the device at all times.

North American Industrial Services, 1240 Saratoga Rd, Ballston Spa, NY 12020. Tel: 518-8851820; Fax: 518-885-7638.