Metallic Power takes fuel cell technology into new frontier

By Cathy Swirbul

Contents

Tiny pellets help create electricity

The power of zinc

Putting that power to work

Removing commercialization roadblocks

If things go as Jeff Colborn plans, golf course managers will maintain greens with commercial mowers that are so quiet, they can be cut in the early morning without waking nearby residents. Colborn also envisions outdoor power equipment that recycles and reuses its fuel—tiny zinc pellets. Sound far-fetched?

Companies like lawn mower manufacturing giant Toro and Briggs & Straton, one of the largest producers of air-cooled gasoline engines for outdoor power equipment, don't think so. In fact, these and several other companies are investing considerable time and money to help develop the chief product of Colborn's company—the zinc/air fuel cell.

Colborn, an MIT graduate with an entrepreneurial bent, knows he has a winning business idea with the zinc/air fuel cell. He launched Metallic Power of Carlsbad, CA in 1995 on that certainty. Fuels cells have caught the eye of energy investors. Some analysts predict a billion-dollar market by 2005.

The fuel cell concept has existed since the early 1800s, but interest has renewed in recent years because of new electronic controls, a better understanding of viable fuels, government research grants and stricter environmental regulations. The zinc/air fuel cell is one product being developed in this promising industry.

Tiny pellets help create electricity(Return to Contents)

The zinc/air fuel cell generates electricity when it combines zinc with oxygen in the presence of an electrolyte, such as the potassium hydroxide used in Metallic Power's cell. The chemical reaction also produces zinc oxide, a non-toxic white powder used in sun block.

In the separate recycling unit, this zinc oxide turns back into fresh zinc fuel using electricity, and the oxygen releases into the air. It is a closed-loop system—with nothing to add, discard or waste.

According to Colborn, the zinc and electrolyte can be reused indefinitely. The fuel cell is quiet, emission-free and provides continuous power. It can be refueled simply by changing the fuel cartridge.

The power of zinc(Return to Contents)

Unlike most other fuel cell technologies currently being explored, Colborn said, the zinc/air fuel cell doesn't require high pressure, high temperature, or fuel reformers, and it uses one of Earth's most abundant elements for fuel.

Zinc differs from hydrogen, the more commonly used fuel for fuel cells, in that it is nonflammable and possesses up to eight times the energy density. The zinc/air fuel cell can produce the same power as the hydrogen PEM fuel cell being developed for vehicle applications, at one-tenth the cost, Colborn said.

Zinc fuel has up to 10 times the energy per pound and per volume when measured against traditional lead-acid batteries. Compared to gasoline engines, the fuel cell has up to three times the energy efficiency, and can be used indoors.

Putting that power to work(Return to Contents)

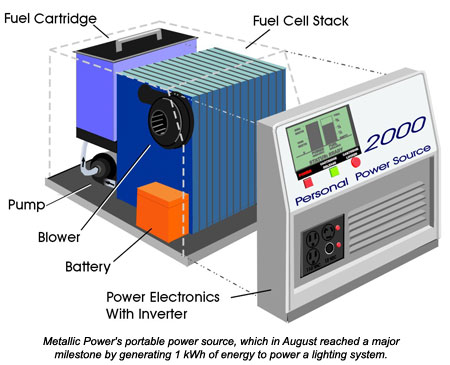

Currently, Metallic Power focuses on the development of a portable power source, containing a zinc/air fuel cell that will deliver 2 kW of continuous power and 4 kW of peak power. Aug. 15, the company made great strides toward that goal when it successfully used the zinc/air fuel cell to provide 1 kWh of energy to power a lighting system.

The event also marked a significant milestone for investors, who include Nth Power Technologies, Arete Corporation, Minnesota Power and Hydro-Quebec Capitech. Corporate investment in Metallic Power amounts to about US$8.5 million. Also, the company has received US$1.5 million in research and development funds from the United States government, the state of California and local governments.

Initially, the product will be used to provide power for emergency home backup, job-site portable power, camping, recreation and the military. These are market niches that can afford higher prices per kW and are more likely to generate near-term profits, Colborn said.

Eventually, the applications will be expanded to include: backup power for businesses and telecommunications; auxiliary power for long-haul trucks, boats and RVs; power for non-road electric vehicles such as forklifts, utility carts and turf equipment; and finally, to on-road electric vehicles.

In addition to Toro and Briggs & Stratton, the following organizations are partnering with Metallic Power:

Removing commercialization roadblocks(Return to Contents)

Metallic Power, Colborn said, faces several challenges on the road to commercialization. These include minimizing the volume of electrolyte that must be pumped in and out of the fuel cell, and maximizing the reliability and efficiency of the recycling hardware while minimizing overall cost.

One challenge Metallic Power recently overcame was developing a low-cost, high-power, durable air cathode. A patent is pending on the company's new air cathode.

However, Colborn remains confident Metallic Power will overcome these challenges. In fact, he expects the company to conduct a beta test in 2001 and a product launch in 2002. The next few years promise great strides in fuel cell commercialization, most analysts contend, and Colborn intends to be part of that.

For detailed product information, contact Susan Connell, marketing communications manager, at info@metallicpower.com. Also, visit www.metallicpower.com.

Hydrogen fuel cells have garnered the attention of researchers and investors alike in recent years, but a technological cousin, the zinc/air fuel cell, may hold as much promise as a clean power source. Metallic Power, based in Carlsbad, CA is one of the cutting-edge developers of this new technology. Jeff Colborn, PhD., founder and CEO, offers an inside look at how his company developed and where zinc/air fuel cells may be headed.

Hydrogen fuel cells have garnered the attention of researchers and investors alike in recent years, but a technological cousin, the zinc/air fuel cell, may hold as much promise as a clean power source. Metallic Power, based in Carlsbad, CA is one of the cutting-edge developers of this new technology. Jeff Colborn, PhD., founder and CEO, offers an inside look at how his company developed and where zinc/air fuel cells may be headed.