GE Power Systems selects GateCycle

The Power Plant Engineering group of GE Power Systems is working with GE Enter Software to establish the GateCycle program as their new standard engineering software for the design and analysis of combined-cycle power systems. GE Power Systems plans to use the GateCycle program in place of internally developed software that GE has relied on for many years. GE recognizes that the GateCycle program, with its modern, easy-to-use Windows interface and commercial-grade software core, is an excellent platform for increasing productivity and will be useable, upgradeable and customizable for many years to come. GE Power Systems joins GE Enter Software's other long-time major customers in the power industry to solidify GateCycle's position as a standard tool for power plant design and analysis.

The GateCycle program was recently included in a comparative evaluation of commercial heat-balance software conducted by VGB, a German industrial association of power and cogeneration utilities. In the VGB study results, GateCycle ranked at or near the top in a number of categories, most significantly for its capabilities in simulating a wide range of existing power plants. The final results from this study will be discussed in an upcoming issue of VGB's magazine (VGB PowerTech, February 2001, "Comparison of Software for Thermodynamic Process Calculation"). Based upon the results of this evaluation, GE Enter Software believes the GateCycle program is clearly the most powerful and flexible all-around application with an attractive cost/performance ratio. More information on this study can be found at the VGB web site at www.vgb-power.de/extern/vgb/wwwsetup.nsf/common/attach/$file/index_en.html.

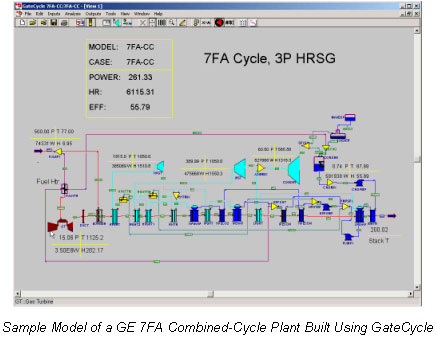

Major advantages of the GateCycle software are its configuration flexibility and the depth and robustness of its engineering models. Using the GateCycle program's intuitive model-building and diagramming tool, based on the PROVISION® interface from Simulation Sciences, a model can be constructed for virtually any power plant by just dropping equipment icons on the screen and connecting the major streams between them. Using built-in data defaults or entering customized data inputs through intuitive, color-coded data entry windows, GateCycle models can quickly be set up to predict the design and off-design performance of a wide variety of energy systems in one integrated package. In addition, the GateCycle program includes complex equipment models to design and analyze more advanced cycles, including major portions of IGCC plants, nuclear steam cycles and advanced gas-turbine designs.

With the GateCycle program, it is easy to customize models, data and calculations for more precise modeling. GateCycle includes a flexible and powerful set of functions called "Macros" that can be used to set up arbitrary calculations and control relationships among GateCycle inputs and calculated results with user-defined equations and data tables. Another recent major enhancement to the GateCycle program is a powerful, flexible built-in optimization solver. This feature enables users to define an arbitrary objective function and then automatically find the GateCycle input values to maximize (or minimize) it.

Another major advantage is that the GateCycle program incorporates detailed design and off-design analysis routines in a single, integrated and consistent analysis framework. The built-in off-design correlations enable quick and accurate equipment and plant performance predictions under various operating and degradation scenarios. This makes it easy to apply the program at various stages of plant design and analysis including preliminary screening, initial conceptual design, detailed engineering design, operational performance analysis, and even advanced-cycle systems studies. The GateCycle program can generate correction curves for acceptance test calculations, and complex GateCycle models have even been configured as contractual on-line acceptance-test calculators. With its flexibility and detailed off-design analysis capabilities, GateCycle can also be used to model existing plants with sufficient detail to evaluate the performance benefits of maintenance actions or plant modifications. GateCycle can be configured to predict plant data at precisely the locations where sensors are situated, a significant benefit for performance monitoring analyses.

The GateCycle package also includes a powerful Microsoft Excel add-in utility, the CycleLink™ software, which gives full access to GateCycle models from Excel spreadsheets. At the simplest level, the CycleLink utility can be used to bring any GateCycle data into a spreadsheet, where calculations can be added or customized reports generated. At a higher level, parametric studies can be run or Excel macro functions programmed to build customized interfaces to GateCycle models. This enables users to deliver full working GateCycle models with an Excel interface.

GE Enter Software is an international engineering software and consulting firm that focuses on increasing the efficiency of power systems at the design and operating stages through the GateCycle, EfficiencyMap and Plant Payback software solutions. In October 2000, GE acquired Enter Software, Inc., which is now part of GE Power Systems. GE Enter Software was founded in 1988, developing state-of-the art software systems for thermal performance, design and diagnostics.

For more information on GateCycle or other power plant software solutions from GE Enter Software, visit our web site at www.gepower.com/enter, e-mail us at ge-enter.info@ps.ge.com or call us at (650) 322-6610, x212.

The names of actual products and companies mentioned herein may be trademarks of their respective owners.

Subscribe to our free e-mail newsletter.

Click for a free Buyer's Guide listing.