Continuous MIcrofiltration (CMF) Systems: The Dependable Pretreatment Solution for Recycling Economical Seconday Sewage

With the cost of "clean" water rising and the need to conserve and recycle water escalating, there is an increasing demand for technologies that can effectively and economically treat secondary sewage from local municipalities for recycle as boiler feed make-up water.

Typically, waters high in total suspended solids (TSS) and total dissolved solids (TDS) are first treatedwith conventional clarification by flocculation/settling and media filtration. The water is then polished with either reverse osmosis (RO) or deionization (DI) before the water is suitable for use as boiler feed. However, conventional clarification/filtration methods are often inadequate, resulting in poor RO performance, fouled membranes and a subsequent increase in operating and maintenance costs.

USFilter CMF Systems: The Superior Method for Pretreating Secondary Sewage for Make-up to RO Systems

Designed to remove particles greater than 0.2 microns, including suspended solids and bacteria, Continuous Microfiltration (CMF) systems use hollow fiber microporous membranes encapsulated into a bundle to form a filter module. Each module is connected by a patented interlocking mechanism that reduces external plumbing requirements.

Key Advantages of Continuous Microfiltration (CMF)

Treating Secondary Sewage at Eraring Power Station for Recycle as Boiler Feed: An Economical and Environmentally Friendly Solution

Australia's Eraring Power Station, owned by Pacific Power Corporation, had a special challenge: find a way to treat secondary sewage from the nearby Dora Creek municipal wastewater plant for recycle as high-quality boiler feedwater. The power plant was sharing potable water with 25,000 homes, resulting in an intermittent supply. Secondary sewage was causing eutrophication of Lake Macquarie, and needed to be piped 10 miles (17 kilometers) to a sea outfall.

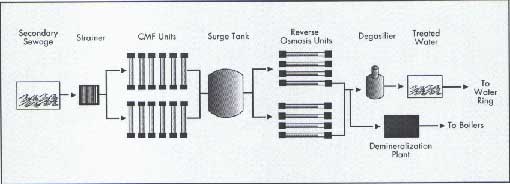

USFilter met the challenge, providing a CMF/RO system to treat the secondary sewage and recycle the treated water to an existing DI unit for producing boiler feed. Pacific Power saw CMF/RO technology as a benchmark for treating and recycling secondary sewage, and a way to substantially reduce annual potable water and demineralized water production costs.

Treated water is fed to the boiler feed DI unit for non-potable water applications, while the RO reject passes through the demineralizer plant wastewater sump to the station ash dam. The backwash from the CMF systems is sent to Pacific Power's onsite wastewater treatment facility and recycled to the feed receiving tank.

Started up in February 1995, the CMF/RO system is producing high-quality boiler feed water and has turned the power station into a zero discharge operation. The system has reduced annual operating costs by approximately $725,000. It has also allowed the plant to reduce the use of regeneration chemicals by 60%, saving $80,000 a year in chemical costs.

USFilter CMF/RO : The best Treatment Alternative for Recycling Economical Secondary Sewage for Boiler Feed Make-up Water

Secondary sewage can be an economical, dependable water source when treated effectively and reliably with a USFilter CMF/RO system. Conventional clarification and filtration methods are not always adequate for treating secondary sewage prior to RO, as the RO membranes may easily foul, resulting in high operating and maintenance costs.

USFilter CMF systems offer many benefits over conventional pretreatment technologies:

These benefits all add up to a winning solution to meet the demands of today's power plants.