CFX: design tool for small hydro

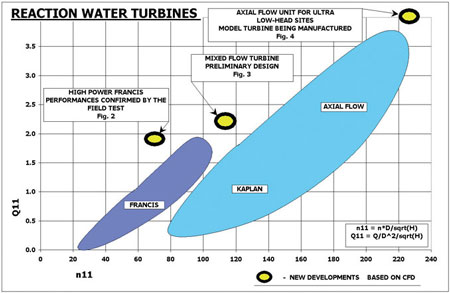

Significantly better machine performance has been realized since large hydro turbine designers have adopted CFD in their normal design practice. A 20% increase in unit power over older designs has been seen in some cases, and other improvements include higher hydraulic efficiency levels and better operational stability.

Historically, the small hydro industry has depended upon developments in large corporations for insight into machine design. With sophisticated research in hydraulic designs being simply too costly for small companies, designs of water turbines for small hydro projects (below 5 MW) were based on solutions developed for large hydro needs.

From the viewpoint of hydraulic performance, small hydro turbines differ from larger ones in many ways, including the need to maximize unit output even at the price of lower hydraulic efficiency. And where old runner replacements are involved, there is demand for low turbine speed while maintaining high unit power output.

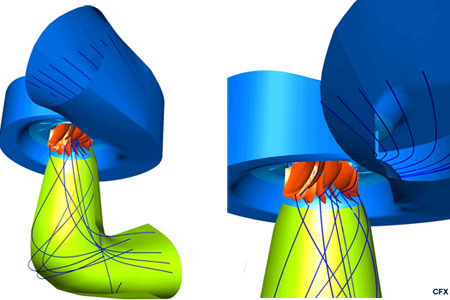

The critical step in designing machines of this type is the hydraulic performance verification. Since CFX-TASCflow has a proven track record in the hydro turbine field, we have decided to use the software to enhance our design and development processes.

To better facilitate the geometry design stage for our unique needs, we have developed a quasi-3D geometry editor to create topology data files for the CFX-TASCflow pre-processor.

We also use the Multiple Frame of Reference capability to provide preliminary design modifications of the "initial guess geometry" (rough optimization) based on a coarse grid (single wicket gate/single blade/draft tube) analysis. Further optimization steps are completed using finer grids with the final verification consisting of the spiral case/all wicket gates/runner/draft tube.

With CFX, small hydro can now take advantage of computational technology to better address their particular requirements.

(About the author: To contact, Swiderski call (613) 829-8248, fax (613) 829-2160, jacek@achilles.net.)

Subscribe to our free e-mail newsletter.

Click for a free Buyer's Guide listing.