AEA Technology Increases Power of Engineering Software

AEA Technology Engineering Software, a Canada-based subsidiary of AEA Technology that supplies engineering solutions for manufacturing, chemical process and power generation industries, recently released the latest version of its of CFX-TASCflow computational fluid dynamics software, giving it more punch.

"CFX-TASCflow has a proven track record of robustness, accuracy and efficiency and was the first commercially available CFD software to have a fully implicit coupled solver," said Glenn Smith, a spokesman for AEA Technology Engineering Software.

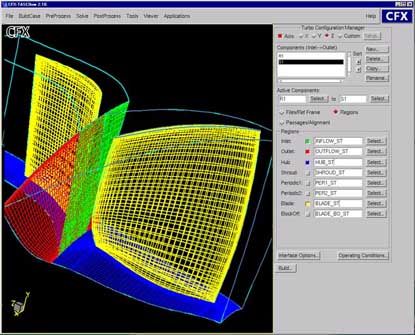

Continuing with this tradition of innovation, Smith said CFX-TASCflow 2.10 provides improvements to turbomachinery preprocessing, which can decrease user setup time by from days to minutes.

The new version's unified environment provides an approach to multiple-component problem setup that allows easier analysis of the entire flow path by automating component alignment and frames, connections, periodicity, operating conditions, initial conditions, material selection, parameter specification and memory management.

CFX-TASCflow Pre-processor for Turbomachinery

CFX-TASCflow pre-processor for turbomachinery streamlines pre-processing, making setup faster and easier than ever before, Smith said. Also, a variety of additional turbulence models allow users to choose the best model for a specific application, increasing accuracy in this highly complex field.

The new version of CFX-TASCflow is now out and includes a ramped up pre-processor for turbomachinery, making the task faster and easier.

A new moving grid capability allows fluid/mechanical interaction analysis. Basic cavitation capabilities impart better understanding of machine performance where cavitation is thought to be present, he said.

Parallelization enhancements permit traditionally computationally intensive applications, such as parallel transient rotor stator analyses, to be performed in less time. Transient results can now be viewed as animations, providing better insight and interpretation for pressure, temperature, velocity and other changes over time.

CFX-TASCflow Cavitation Analysis

The new cavitation model in CFX-TASCflow allows visualization of cavitation zones. See the following graphic as an example.

Cavitation bubble grows with decreasing NPSH (clockwise).

And, AEA's mesh generation tool, CFX-TurboGrid V1.5, is also being released within the next few months with improvements including a tandem-vane template.

CFX-TASCflow remains the centerpiece of CFX's integrated suite of computational fluid dynamics software for rotating machinery design and analysis, Smith said. By using these software tools, designs can be optimized providing a better design before prototype. This suite also includes CFX-BladeGen for design of bladed rows. CFX-TASCflow is available on UNIX and Windows NT starting at US$22,000 for an annual license.

AEA Technology employs about 4,500 people in 26 locations around the world, bringing science to the marketplace through consulting, technical services, hardware and software systems, research and development and technology transfer. For more information on its subsidiary AEA Technology Engineering Software, www.software.aeat.com, or contact Glenn Smith, 519-886-8435, smith@asc.on.ca, or Chris Reeves, 519-886-8435, info@engsw.aeat.com.

Edited by April C. Murelio

editor@poweronline.com