ABB, Process Systems Enterprise Announce Tech Services Agreement

Automation engineers in the process industries now have a new tool for modeling and optimizing production systems. ABB Automation, part of the Geneva-based ABB Group, recently struck a deal with Process Systems Enterprise (PSE) to be the exclusive licensee for control and optimization applications of gProms.

The Centre for Process Systems Engineering at Imperial College (London) developed the gProms program. PSE is the privately held spin-off from the Centre.

Since its commercial introduction in 1997, more than 100 chemical, food, pharmaceutical and other process manufacturers use gProms for design, control and optimization projects. Clients include Bayer, ICI, DuPont, Dow Chemical, BASF, and Mitsubishi Chemical. Many of the existing applications have been in designing process equipment and production steps, particularly in batch processing.

The licensee agreement includes software licensing and services and opens up more control applications for ABB Automation, including steady-state and dynamic optimization and parameter characterization.

Solver engines

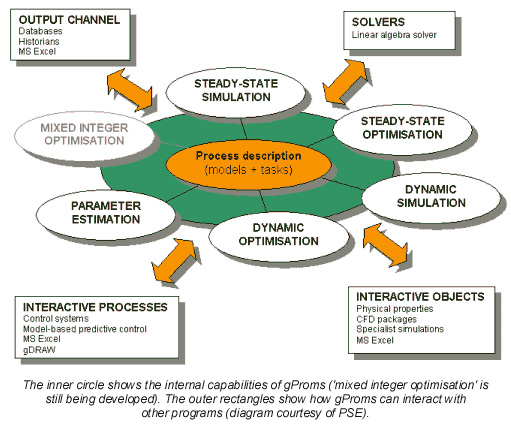

According to PSE literature, the standout property of gProms ("General PROcess Modeling System") is that it provides a robust method to interface the modeling system with "solver engines"—related programs for thermodynamics, physical properties, even computational fluid dynamics (see diagram). With its modular structure, a gProms process model can fetch necessary process data from these solvers, then produce a high-fidelity simulation of a process for further engineering analysis.

"Competing packages require you to build one model for, say, steady-state simulation, then another model for dynamic optimization," said Mark Matzopoulos, managing director of PSE. "With gProms, you build one model and use it for multiple applications."

Also, the underlying software with a design that's object-oriented, modular, and has open (published) interfaces allows it to be used on common operating systems (Windows, Unix, Linux) and to interface to Web protocols. "This flexibility is perfect for the mixed computing environments of large process manufacturers," said Sandro Macchietto, nonexecutive chairman at PSE. "You can run the model on a Unix system, obtain data from a Windows system, and display results on your Palm Pilot."

Model library

According to Steve Sussman, ABB Automation business manager, ABB conducted an exhaustive search of available technology before choosing gProms. This may be a case of the right key finding the right lock. The modularity of the gProms technology will allow ABB to more readily adapt it to the large family of somewhat incompatible control systems that it has acquired over the past decade, including its own Advant Open Control System, Elsag Bailey, Fischer and Porter, Hartman and Braun, and others.

In addition, ABB Automation plans to bring its strong focus on vertical market segments in the process industries. ABB tailors solutions for chemical, pharmaceutical, pulp and paper, and other industries. The company will be providing comprehensive services along with the gProms technology, and will work with PSE to build up a "model library" of preconfigured applications, which customers can then plug into their control or engineering systems. ABB Automation is currently styling itself as an "industrial IT" supplier. Sussman said that gProms allows it to provide the "highest value-added solutions" to the control arena.

New gProms/ABB solutions will begin to roll out in the fourth quarter, according to Zafar Kamal, global business manager for advanced systems at ABB Automation. The more advanced applications, such as dynamic optimization, parameter estimation, and planning and scheduling will follow. The technology will be offered in three levels: basic software licensing and services; the plus model libraries incorporating specific ABB process knowledge; and custom-built applications. PSE retains the rights to market gProms for offline design applications.

For more information about gProms, call ABB Automation, 41 (0) 1 319 6222, or PSE, 44 (0) 20 8563 0888.

By Nick Basta, Hydrocarbon Online managing editor