GTI Uses Gasified Waste To Generate Electricity

Green Power from Chicken Litter: GTI Uses Gasified Waste to Generate Electricity with a Solid Oxide Fuel Cell

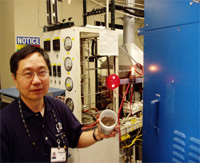

Des Plaines, IL — Gas Technology Institute (GTI) has successfully demonstrated that chicken litter can be gasified to produce hydrogen and generate electricity using a solid oxide fuel cell (SOFC). Under a project funded by the U.S. Department of Agriculture, Earth Resources, Inc. (prime contractor), GTI, and the University of Georgia are working to convert chicken litter into energy and fertilizer. As part of this USDA-funded project, GTI conducted a test to demonstrate the suitability of chicken litter as a low-Btu fuel for the SOFC.

Des Plaines, IL — Gas Technology Institute (GTI) has successfully demonstrated that chicken litter can be gasified to produce hydrogen and generate electricity using a solid oxide fuel cell (SOFC). Under a project funded by the U.S. Department of Agriculture, Earth Resources, Inc. (prime contractor), GTI, and the University of Georgia are working to convert chicken litter into energy and fertilizer. As part of this USDA-funded project, GTI conducted a test to demonstrate the suitability of chicken litter as a low-Btu fuel for the SOFC.

Litter from poultry farms is traditionally used in land applications as a fertilizer because it is rich in nutrients. But the rise in poultry production combined with the decreasing availability of land and potential deleterious environmental impacts creates concern about traditional litter disposal methods. Gasification has the potential to provide a cost-effective, environmentally benign disposal option for the litter while providing heat, power, fuel (such as hydrogen) and fertilizer.

According to Francis Lau, Director of Corporate Development at GTI, "Commercialization and implementation of such a modular technology has the potential to generate on-site power and heat from a renewable source of energy economically while addressing environmental problems caused by traditional disposal practices. Also, chicken litter can replace fossil fuels currently used to provide heat in poultry farms, thus avoiding net generation of CO2. GTI is pursuing the development and commercialization of this technology."

The fuel gas was produced in a bench-scale fluidized bed gasifier operated at 1550°F with the chicken litter feed. Air and steam were used as the gasifying medium. A 5-cell SOFC stack was operated at 1470°F on the slipstream from the gasifier. A zinc oxide (ZnO)-based sorbent bed was used to remove H2S in the fuel gas prior to entering the SOFC stack. An average power density is about 40% of that obtained from reformed natural gas due to this low-Btu (80 Btu/ft3) fuel. Post-test disassembly confirmed no carbon deposition on the SOFC nickel anode and did not indicate any unusual state of the stack active components.

The fuel gas was produced in a bench-scale fluidized bed gasifier operated at 1550°F with the chicken litter feed. Air and steam were used as the gasifying medium. A 5-cell SOFC stack was operated at 1470°F on the slipstream from the gasifier. A zinc oxide (ZnO)-based sorbent bed was used to remove H2S in the fuel gas prior to entering the SOFC stack. An average power density is about 40% of that obtained from reformed natural gas due to this low-Btu (80 Btu/ft3) fuel. Post-test disassembly confirmed no carbon deposition on the SOFC nickel anode and did not indicate any unusual state of the stack active components.

SOURCE: Gas Technology Institute