Advanced Power Analytical Systems

Leading-edge instruments; applications expertise; unmatched customer service; worldwide support – that’s what makes Emerson instruments the world leader in power plant analysis. We offer a complete range of analyzers, transmitters and sensors for continuous on-line measurement of liquid and gas processes as well as flame and gas safety monitoring for process industries. To review the Advanced Power Analytical Solutions brochure click HERE, and continue reading for additional technology information.

Liquid Analysis

Corrosion costs the electric power industry billions of dollars a year in damaged equipment and power replacement costs. Although corrosion can never be eliminated, it can be significantly controlled by good water chemistry. Reliable measurement of process conditions is central to that control.

Feedwater pH is one of the most difficult measurements to make in a power plant, but the Rosemount Model 3200HP pH sensor makes the job easy. The gravity-fed flowing junction reference ensures a small, stable liquid junction potential even in samples having conductivity as low as 0.3 µS/cm. The result is a measurement error no greater than ±0.05 pH after buffer calibration. The 3200HP has almost no sensitivity to changes in sample flow.

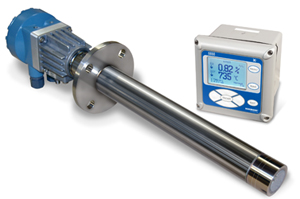

Combustion Solutions

Combustion flue gas analysis has been used for decades as a method of optimizing fuel/air ratio. By measuring the amount of excess oxygen and/or CO in the flue gases resulting from combustion, users can operate at the best heat rate efficiency and lowest NOx, while also generating the least amount of greenhouse gas. The Rosemount Model 6888 Oxymitter uses zirconium oxide fuel cell technology, integrating it with field electronics into a single, compact package. Its probe inserts directly into a flue gas duct to measure oxygen in combustion processes – no sampling system is required. The Oxymitter electronics also require 95% less power to operate, so the components last longer.

Gas Analysis

The quality and composition of fuel burned in gas turbines or natural-gas-fired burners has a tremendous impact on the life span and maintenance requirements of the plant asset. Emerson gas chromatographs (GC’s) offer the most reliable and cost-effective solution for your process and natural gas measurement needs. Emerson GCs let users achieve maximum accuracy and measurability of their gas components to help monitor combustion, emissions, and other critical applications. The 700XA Gas Chromatograph from Rosemount is engineered for increased flexibility, ease of use, and improved online measurement performance.

Continuous Emissions Monitoring Systems (CEMS) help keep power plant emissions in compliance with local regulatory agencies. Rosemount CEMS range from pre-engineered, packaged systems to more complex custom-engineered systems that measure multiple gases using data acquisition and handling. They are designed to perform the required daily zero and span checks automatically and unattended. Automatic calibration makes it less costly and time consuming to meet the environmental requirements for daily validation of the systems. The Rosemount CEMS monitor the following:

- Sulfur Dioxide (SO2)

- Nitrogen Monoxide (NO)

- Nitrogen Dioxide (NO2)

- Carbon Dioxide (CO2)

- Oxygen (O2)

- Carbon Monoxide (CO)

- Total Hydrocarbon (THC)

- Hydrogen Sulfide (H2S)

- Opacity

Gas and Flame Safety Monitoring

The Emerson range of flame detectors and fixed toxic/combustible gas detectors are designed to excel in the most challenging power generation environments. Power plants often utilize hydrogen as a coolant in many areas of operation which is highly combustible and has an invisible flame that is difficult to detect. Toxic gas such as chlorine, carbon monoxide, and methane are also serious potential hazards for plant personnel. For locations where flue gas or CO2 are used for inverting coal storage vessels, O2 deficiency monitors are also required. Coal-fired power plants have some extra monitoring requirements as well; the characteristics of coal, as well as the handling of it in large quantities, require fast and accurate flame and gas detection.

Many hazards are constantly present within power generation applications, and they each present unique considerations when selecting a detection technology. Net Safety Monitoring offers a wide range of safety monitoring instrumentation which can provide the optimal solution, with intelligent design features that simplify maintenance and lower costs.